STRATUS STEEL : ADOPTING LIGHT GAUGE STEEL FRAMING TECHNOLOGY FOR THE PRADHAN MANTRI AWAS YOJANA

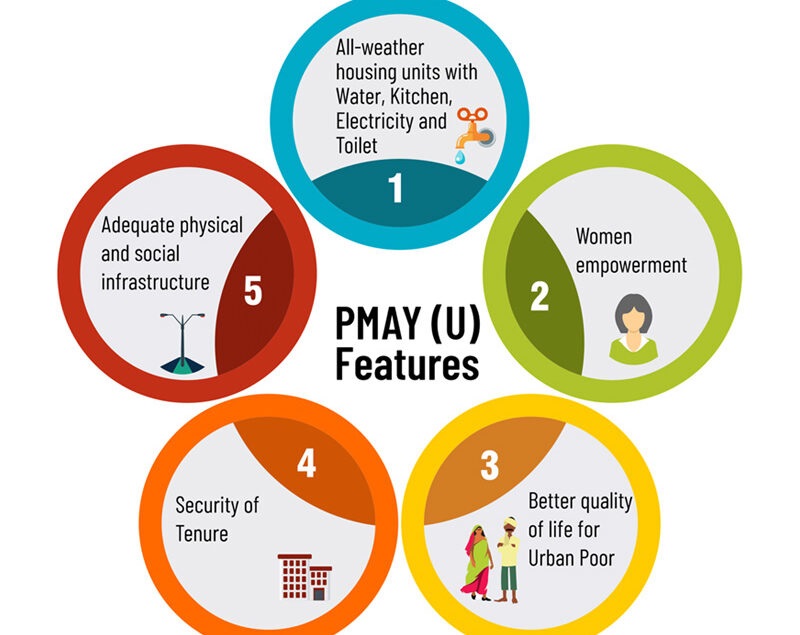

As a part of the continuous efforts of the Indian Government to fulfill the housing needs of rural and urban poor, Pradhan Mantri Awas Yojana was launched by Prime Minister Narendra Modi in June 2015 with an aim to provide affordable housing.

What is Pradhan Mantri Awas Yojana?

Pradhan Mantri Awas Yojana – Urban (PMAY-U), a flagship mission of the Government of India being implemented by the Ministry of Housing and Urban Affairs (MoHUA), was launched on the 25th of June 2015. The Mission addresses urban housing shortage among the EWS/LIG and MIG categories including the slum dwellers by ensuring a pucca house to all eligible urban households by the year 2022 when the Nation completes 75 years of its Independence.

Why was PMAY started?

Urban India suffers from a massive shortage of adequate housing. The number of households living in inadequate housing conditions was estimated to be 4.7 crores in 2018 in urban India (Roy & Meera, 2020).

The Government of India, under the Pradhan Mantri Awas Yojana – Urban, assessed an aggregate ‘validated’ demand of 1.12 crore houses (Lok Sabha, 2021). 6 The demand for affordable housing is expected to grow in the decades to come as India urbanizes rapidly, with the urban population to total population ratio of 34.9 percent in 2020 expected to rise to 52.8 percent in 2050, and as incomes grow with economic growth (World Urbanization Prospects: The 2018 Revision, 2019).

Massive reverse migration from Indian cities during the ‘lockdowns’ imposed in the first wave of the COVID-19 pandemic in 2020 reflects that the poor migrant laborers lacked safe and affordable shelter for their families in these cities. To supply adequate housing to the lower- and middle-income segments in Indian cities, mass housing projects i.e., large complexes containing about 500 or more apartments, situated in urban and suburban areas will gain importance.

The conventional on-site process of construction uses cement concrete and steel reinforcement to form reinforced cement concrete (RCC) used to build a framework of beams (horizontal members) and columns (vertical members).

Subsequently, walls are constructed using brick masonry and floors are cast on-site. This conventional process has limitations, particularly for large-scale mass housing projects (Building Materials & Technology Promotion Council, 2021). Assembling the timber-based formwork (i.e., molds into which the concrete is poured) at the construction site is time-consuming, lacks repeatability, and is of poor quality and durability. Building the superstructure (i.e., the portion of the building above the ground level) in the open uncontrolled environment of a construction site exposes the project to weather disruptions and makes it difficult to monitor the quality of construction.

This, in several cases, leads to inordinate delays, cost overruns, large quantities of construction waste, and suboptimal quality of the end product.

WHY IS THERE A NEED FOR ALTERNATIVE METHODS OF CONSTRUCTION WITH REGARD TO AFFORDABLE HOUSING?

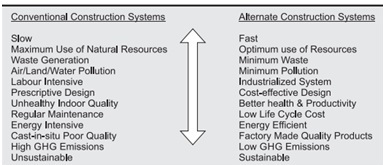

There are several advantages of a shift to alternate construction methods from the conventional on-site RCC process. Most often, alternate construction technologies shift a part of the construction process to a factory location where the building components are manufactured at a rapid pace in a controlled environment. This reduces the construction time, often by as much as half the time estimated for conventional on-site construction.

The reduced construction time results in substantial cost savings by reducing the interest liability and providing quicker returns on investment. The quality of construction is superior since it is mechanized and produced in a controlled factory environment.

The higher predictability that comes with the use of machines enables better planning and, therefore, optimal resource utilization. Fewer unskilled laborers are required at the construction site reducing the human resource management burden for construction firms.

The use of these alternate construction processes also reduces the risk of accidents at the construction site.

There are substantial environmental benefits from a shift to alternate construction processes as they reduce water consumption, optimize the use of resources, reduce the quantity of construction waste generated and are likely to have a lower overall carbon footprint. With global and national priorities aligned to limit climate change, this is another important driver for increasing the uptake of alternate construction technologies. It is important to point out, however, that the reduction in carbon footprint is also determined to a large extent by the design, the materials used and the transportation requirements other than the technology used.

Considering the substantial advantages that the new technologies offer, the Government of India under the Pradhan Mantri Awas Yojana – Urban (2015) added a Technology Submission to ‘facilitate the adoption of modern, innovative, and green technologies and building material for faster and quality construction of houses’ (Ministry of Housing & Urban Poverty Alleviation, Government of India, 2015).

ABOUT THE LIGHT GUAGE STEEL FRAMING TECHNOLOGY :

LGSF frames assembled to form a structure. This structure will then be clad to form a final finish

Light Gauge Steel Framed Structures (LGSF) is based on factory-made galvanized light gauge steel components, designed as per codal requirements, produced by cold forming method, and assembled as panels at site forming structural steel framework of a building of varying sizes of wall and floor.

The basic building elements of light gauge steel framing are cold-formed sections that can be prefabricated on-site using various methods of connection. The assembly is done using special types of screws and bolts.

Cold-formed sections are widely used in construction including residential floors, industrial buildings, commercial buildings, and hotels and are gaining greater acceptance in the residential sector. LGSF is already well established in residential construction in North America, Australia and Japan and is gaining ground in India.

LGSF is typically ideal for one to three-story high buildings, especially in residential homes, apartments, and commercial buildings. Due to its flexibility fast construction and durability, this technology has great potential for counties like India.

LGSF can be combined with a composite steel / concrete deck resting on light steel framing stud walls. Apart from having potential for mass housing, modular buildings can be used for long-term temporary or permanent structures such as schools and classrooms, military and civil housing needs, post-disaster relief structures and industrial buildings.

Why is Light Guage Steel Framing Technology, the Best pick for construction under Pradhan Mantri Awas Yojana?

We, at Stratus Steel, have always seen LGSF as a one- size-fits-all type of solution. It is extremely flexible and durable. As people become more aware of technological advancements LGSF will eventually replace conventional civil construction in many areas. LGSF is an emerging technology and the Hon’ble Prime Minister Mr. Narendra Modi Ji took note of it as a clean, green and emerging technology in one of his speeches.

Abiding by Pradhan Mantri Awas Yojana and our Hon’ble Prime Minister Mr. Narendra Modi Ji’s vision of ‘Housing For All’, the LGSF technology has been developed around this ideology for producing faster mass housing in India.

The focus is on the ‘double-the-speed’ concept compared to the traditional mode of construction. LGSF frames are flexible, lightweight, and manufactured and disassembled off-site, they can be quickly assembled and installed on-site, making them ideal for mass housing.

This form of dry construction also requires minimal manpower. For high-rise buildings in mass housing light gauge steel reduces the entire weight of the building as finishing is quite superior. Light Gauge Steel has given way to faster, affordable and quality homes thereby serving the PMAY purpose.

Now, moving to the question that might be lingering on your minds – WHY REPLACE CONVENTIONAL METHODS WITH LGSF?

LGSF offers unparalleled benefits over other technologies, when it comes to strength to weight ratio,

seismic & wind resistance, with better pest & mold resistance. It is an eco-friendly construction technology that is non-combustible and built to precision. For affordable housing solutions, this is the best mode of construction one can go for.

Having said that, let’s quickly scan through the many benefits of picking LGSF over conventional construction methods:

- Superior Construction Material: The steel sheets that form the light gauge steel frames are neither vulnerable to any sort of fungi or organism nor are combustible. This makes it a secure, safe and perfect choice for construction material. Steel is inorganic and so will not rot, warp, crack, or creep and is dimensionally stable, therefore not expanding or contracting with moisture content.

- Cutting edge, green technology: It is the future; LGSF is green, environmentally friendly and has energy efficient properties that allow very little waste (negligible) as all the steel is cut to fit exactly. LGSF generates low construction waste and provides environmental benefits, including lesser CO2 emissions, lesser freshwater utilization and higher recyclability of steel components.

- Less pressure on foundations: The steel used is lighter than other materials but has more strength which puts less pressure on the foundation making it the ideal choice to lay foundations too.

- Speed of Construction: The construction time can be cut down drastically as everything can be prepared at an off-site location just like Lego blocks and even pre-drilled for services.

- Lesser chances of Human Error: The light gauge steel frame method of construction is carried through the use of computers and technology that cuts, rolls or collaborates all the structures without the use of physical manpower. This reduces the risk of error as there is less or zero human interference.

- High tolerance: LGSF structures are extremely robust and resistant to seismic disturbances as compared to traditional RCC structures. Construction in difficult and harsh terrains is possible using LGSF.

- Design Flexibility: Due to its strength, steel can span longer lengths, offering larger open spaces and increased design flexibility without requiring intermediate columns or load-bearing walls.

All aforementioned points make LGSF a better choice when it comes to swift, affordable and advanced construction under the PMAY.

CONCLUSION;

India is a young, rapidly growing country. Both the government and private sector is seeing fast growth. With the lack of housing, LGSF offers a one-size-fits-all type of solution. It is extremely flexible and durable. As people become more aware of tech advancements LGSF will replace conventional civil construction in many areas.

LGSF is an emerging technology and even the Hon’ble Prime Minister Mr. Narendra Modi took note of it as a clean, green and emerging technology in one of his speeches.

While conventional techniques suffer from time, weather and design constraints, LGSF offer a faster, flexible solution, you just ship your prefabs to the site and assemble them. The technology is also greener and cleaner. As everything is pre-calculated there is little chance of cost overruns. LGSF maximizes speed and minimizes wastage and ensures optimal cost benefits.

LGSF as a technology is aligned with the vision of our Hon’ble PM Mr. Narendra Modi and is a partner in the country’s progress. We, at Stratus Steel, are proud to be serving this vision in India.